Pen Project

Idea

I want a nice pen to start grad school. I want it to feel nice in my hand, and be made of metal.

Things to do

- Finish CADing the bolt action ✅ 2025-05-27

- Barrel ✅ 2025-05-26

- Model travel ✅ 2025-05-26

- Split up cap and tip close to the middle ✅ 2025-05-27

- Figure out how to model track in cap ✅ 2025-05-27

- Add set screw to tune cartridge length?

- Print a functional prototype ✅ 2025-05-27

- Figure out how to make technical drawings from the FreeCAD model ✅ 2025-05-27

- Order material (1/2 in steel rod?)

- Figure out the thing about metals potentially binding together?

- Figure out how to thread the parts together (how much overlap, what pitch, thread relief, etc…)

- Add angles to drawing ✅ 2025-05-27

- tighter tip angle?

Log

Thursday Jun 12 2025

- Made some inner threads using a tap and a similar piece of stock. It worked okay, there’s always a bunch of fiddling with finding the right drill bits and taps and whatnot, but it worked!

Wednesday Jun 11 2025

- Tried to make some threads on the lathe. I was aiming for 3/8-24 threads and I… mostly go there?

- A lot of time was spent finding the tools, making sure their height was on the lathe centerline, and setting up the machine

- I also decided to actually program the entire operation manually, so the initial turning and programming took a while

- Notably, I couldn’t program some hacky thread relief with the tool I had loaded, which is reasonable, but I didn’t necessarily expect

- Once programmed, this was pretty quick

- Stock deflection was very noticeable however, doing it again with tailstock support significantly changed the part.

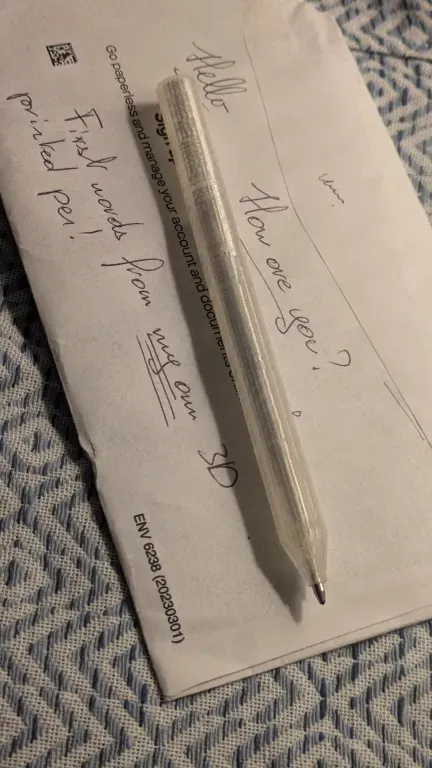

Look, it kinda works!

Tuesday May 27 2025

- Technical drawing! tech-drawings.pdf

Monday May 26 2025

- Printed a functional pen!!

I have made a “working” 3D printed pen! 🖋️ This is my first non-trivial CAD project, and the first pen I can actually write with. The goal for this was to check that everything fit together with a real pen cartridge (it does!) and feels at least reasonable in my hand (it does!). I fully did not expect the machine tolerances (some parts have 0 clearance) to work out in my favor, but it seems like it did, so the pen actually just “works”.

I have made a “working” 3D printed pen! 🖋️ This is my first non-trivial CAD project, and the first pen I can actually write with. The goal for this was to check that everything fit together with a real pen cartridge (it does!) and feels at least reasonable in my hand (it does!). I fully did not expect the machine tolerances (some parts have 0 clearance) to work out in my favor, but it seems like it did, so the pen actually just “works”.

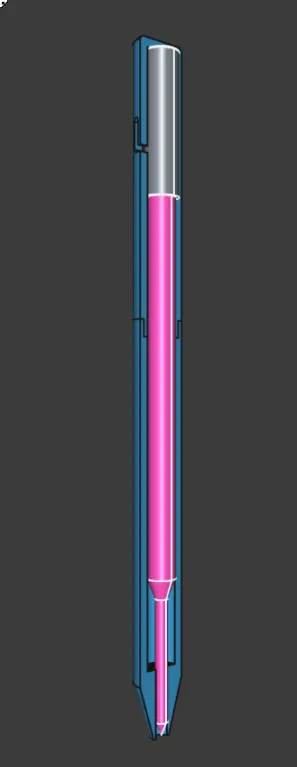

There are 3 parts to the pen: two for the body (tip and cap), and the barrel in the middle which is the thing that will push the cartridge back and forth (I’m calling that the “barrel”, although idk the right name). The only thing I don’t have working with this pen is a way to move it in and out. That requires a thing to attach to the barrel and stick out through the slot in the cap. This is the last thing I’d really like to test on this pen before starting to machine this. (But it’s a little tricky, because the barrel+bolt combo needs to come in two parts or the barrel can’t be assembled into the cap)

- Fill in the details here

Future pens (explicitly, not the current one)

- Engraving the barrel

- Twist-action

- Infinite-twist action

- Use a parker refill? (maybe for the current one too)

- Use brass or copper